38 beer brewing process diagram

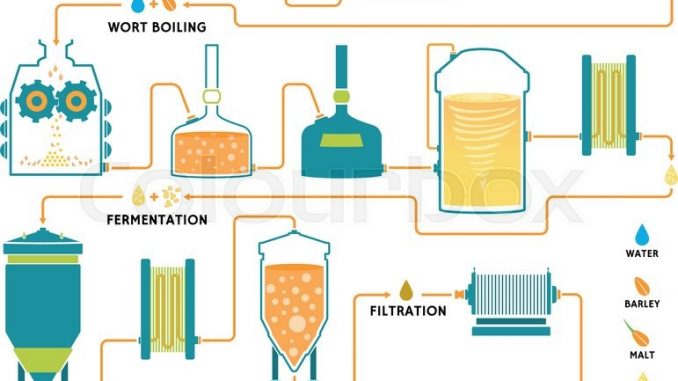

PDF Brewery By-Products Process Flow Chart - Beer Institute Brewery By-Products Process Flow Chart BREWERY TO LAUTERN TUN/MASH MIXER Notes This is the barley process flow. Oats, rice and corn follow similar process steps. Receipt of Malted Barley at Brewery Transfer of malted barley to malt silo Testing and Inspection Prior to Unloading Transfer of stored malted barley to mill START Malt Silo Lautern ... Diagram of the Process of Brewing Beer. Detailed ... Illustration about a detailed diagram of the brewing process. Illustration of drink, brewing, glass - 186984948

A nice commercial brewing process diagram | Beer Diary A nice commercial brewing process diagram. December 18, 2012 · by etripp · in General Geekery · Leave a comment. Not doing much posting (or anything) while I work on remodeling my kitchen… but I thought this diagram was pretty cool. A nice thing to share with beer-curious friends/co-workers. Tags: commercial brewing, diagram.

Beer brewing process diagram

9 Beer Diagrams ideas | beer, craft beer, brewing Mar 9, 2015 - inspiration for an upcoming mural by me, Caryn Cast!. See more ideas about beer, craft beer, brewing. The Beer Brewing Process Explained - Microbrewery.com The process starts with the brewer soaking barley kernels in hot water. Barley kernels or the grains that are being used for beer brewing are crushed for the purpose. This phase is referred to as steeping. The time of soaking is about 40 hours. The temperature of water depends on the type of malt and grain. Understanding the beer fermentation process - The Pure Brewer The beer fermentation process 101. ... This is the last step in beer making. In home brewing, the most simple method is to BOTTLE your beer. At this point you have hopefully a clear, delicious beer. However, since most of the CO2 has escaped during the fermentation, it is quite flat. This is the reason why it should be CONDITIONED.

Beer brewing process diagram. PDF Instrumentation in the brewing industry Automation of the ... Brewing beer requires dealing with naturally grown products changing from year-to-year, harvest-to-harvest. The brewer needs to react on these changes to prepare a stable quality of beer, and even more, it must taste the same all year, each and every year, to fulfill the expectation of the customer. To follow this moving target, Learn the Step-by-Step Process Of Brewing Beer, Explained ... While most of us love beer, few of us know exactly how it's made. Global brewing company SABMiller released a super informative animated video that breaks down the brewing process into its most basic components.. The company says it has released the three-and-a-half minute motion graphic video with the goal of explaining a "technically complex process correctly, simply, and without fuss." The Process of Brewing Beer - Visual.ly The Process of Brewing Beer. The Process of Brewing Beer Ingredients Water Malted Barley (the starch source) Brewer's Yeast Hops Other starch sources Corn, rice, sugar, millet, sorghum, cassava root, potato, agave Potato is used in Brazil Agave is used in Mexico Process Step 1: Malting Malting is the process where barley grain is made ready for ... Brewing | Beer Wiki | Fandom A brew kettle at Anchor Brewing Company. Brewing is the production of beer by steeping malt (most commonly, barley) in water and fermenting the resulting sweet liquid with yeast.It may be done in a brewery by a commercial brewer, at home by a homebrewer, or by a variety of traditional methods, such as communally by the indigenous peoples in Brazil when making cauim.

How to Ferment Beer: A Step-by-Step Guide - Brew Fuse Wait for a week or two depending on the type of beer for the process to complete. 7. Bottle/Keg Your Beer You should notice that the bubbling in your airlock has greatly reduced or stopped completely once your beer is done fermenting. Depending on the type of beer, this should be within a week or two of pitching the yeast. Beer brewing: the brewing process | Braeu am Berg The brewing process is made up of ten production steps from the fresh barley to the finished beer - we would like to present these steps in more detail. The brewing process begins with malting, milling, mashing and lautering. 1 malting soaking germinate kilning 2 milling mashing 3 lautering 4 The 10 steps of the brewing process 1. Malting Beer Processing PFD | Free Beer Processing PFD Templates Beer Processing PFD Template. Providing downloadable free PID and PFD templates to map your process flow visually. Here is a simple beer processing pfd example created by Edraw PID software, which can be transformed into many different formats. Beer Processing PFD. Brewing Process Step-By-Step - Micet Craft To help you better understand the brewing process, I have made a small flow chart, which contains all the steps required to make beer. It also shows where the four main ingredients (water, malt, hops, and yeast) are added in this process. Hope it can help you better understand the brewing process.

How is Beer Made? The Complete Brewing Process Brewing is a science project based on quality ingredients, proper equipment, and math. You need to calculate the exact ratio of ingredients, the brewing time, the beer strength, and bitterness. If you are a novice homebrewer, you can make the process easier by using starter kits, precision recipes, and online calculators. Brewing Process Step-By-Step - With Pictures - Asian Beer ... Brewing Process Step-By-Step - The Stages. To help with the brewing process I've made a little flow chart (see below) of the various steps you need to go through to make beer. It also shows where the four main ingredients (water, malt, hops and yeast) are added during the process. Beer Produce Diagram The Brewing Process We are pleased to provide you with the picture named Beer Produce Diagram The Brewing Process.We hope this picture Beer Produce Diagram The Brewing Process can help you study and research. for more anatomy content please follow us and visit our website: . Anatomynote.com found Beer Produce Diagram The Brewing Process from plenty of anatomical pictures on the internet. A schematic of the brewing process for the production of ... Download scientific diagram | A schematic of the brewing process for the production of Irish red ale outlining the sampling points for the brewing materials, by-products, wort, and beer as ...

The Brewing Process Diagram - Brookston Beer Bulletin The Brewing Process Diagram. Today's infographic is another diagram of the Brewing Process, this one from the Beer Masons, a beer appreciation society in Australia. Click here to see the diagram full size. One interesting addition is they point out that beer is known by many names in the process from grain to glass, and list them in a flowchart.

Process - Bozeman Brewing Company The Process Ingredients WATER - The universal solvent, which makes up 85% to 95% of beer. The worlds most famous breweries are a direct result of their water supply. MALT- A cereal grain that has been steeped, germinated and kiln dried. Malt contributes 100% of color and fermentable extract. HOPS - Green cone like […]

Beer Brewing Process - A Step By Step Guide! - Discover ... The beer is kept for aging from few months to few years followed by bottling and is then ready for commercial use. See How Beer Is Packaged/Canned With Flow Chart. Quantitative Parameters for Beer. Brewers considers these parameters to ensure the perfect beer brewing process. 1.Appearance. 2.Aroma. 3.Flavor. 4.Mouth-feel. 5.Alcohol Content :

Craft Beer Production - University of Pennsylvania As the market demand for craft brewed beer continues to grow, small brewers are continuing to crop up to meet the demand. With the increasing number of small breweries also comes an increasing number of brewery closings—more than 80 since 2010. While the brewing process fundamentals can be mastered

Process Flow Chart for Your Beer Process - rapidmicrobiology Quality Control solutions by Sartorius help you focus on consumer safety and your own unique taste. Because taste is key. Discover in this process flow chart the different steps in the beer workflow and get to know the variety of applications and solutions Sartorius offers for testing your brewing process: Moisture Determination.

industrial brew flow chart. | Beer brewing process, Beer ... Brewing Process Water, malt, hops and yeast - just 4 ingredients (see Our Beers section for more information). How hard can brewing be? Well to be honest it is a pretty straightforward process, the trick is to correctly manipulate all the variables to get the desired and consistent result.

A nice commercial brewing process diagram | Beer making ... Brewing Process At the Potosi Brewery, our brewing process combines old world traditional methods with state-of-the-art modern equipment, and utilizes only the finest raw materials obtainable. Mix all of that with our brewers' passion for the craft and conscientious attention to detail and you get beer that is not only delicious, but ...

(PDF) The beer brewing process: wort production and beer ... The beer brewing process: wort production and beer fermentation. Handbook of food products manufacturing, 1st edn. …, 2007. Ronnie Willaert. Download Download PDF. Full PDF Package Download Full PDF Package. This Paper. A short summary of this paper. 37 Full PDFs related to this paper.

(PDF) Review: Beer Production - ResearchGate c. process of beer production: brewing Brewing is a huge-scale complex proce ss that transforms water, grains and hop to produce what we call beer, and this is achieved mostly with the help of yeast.

Beer Charts | Brewer's Friend Charts to help in your home brewing process and understanding of beer: Beer Style Charts: Beer styles range in alcohol, color, bitterness and original gravity / final gravity. Beer Styles - ABV Chart Beer Styles - IBU Chart Beer Styles - OG/FG Chart Beer Styles - SRM Chart Infographics: Infographic: How Far Will Home

Understanding the beer fermentation process - The Pure Brewer The beer fermentation process 101. ... This is the last step in beer making. In home brewing, the most simple method is to BOTTLE your beer. At this point you have hopefully a clear, delicious beer. However, since most of the CO2 has escaped during the fermentation, it is quite flat. This is the reason why it should be CONDITIONED.

The Beer Brewing Process Explained - Microbrewery.com The process starts with the brewer soaking barley kernels in hot water. Barley kernels or the grains that are being used for beer brewing are crushed for the purpose. This phase is referred to as steeping. The time of soaking is about 40 hours. The temperature of water depends on the type of malt and grain.

9 Beer Diagrams ideas | beer, craft beer, brewing Mar 9, 2015 - inspiration for an upcoming mural by me, Caryn Cast!. See more ideas about beer, craft beer, brewing.

0 Response to "38 beer brewing process diagram"

Post a Comment