40 phase diagram of steel

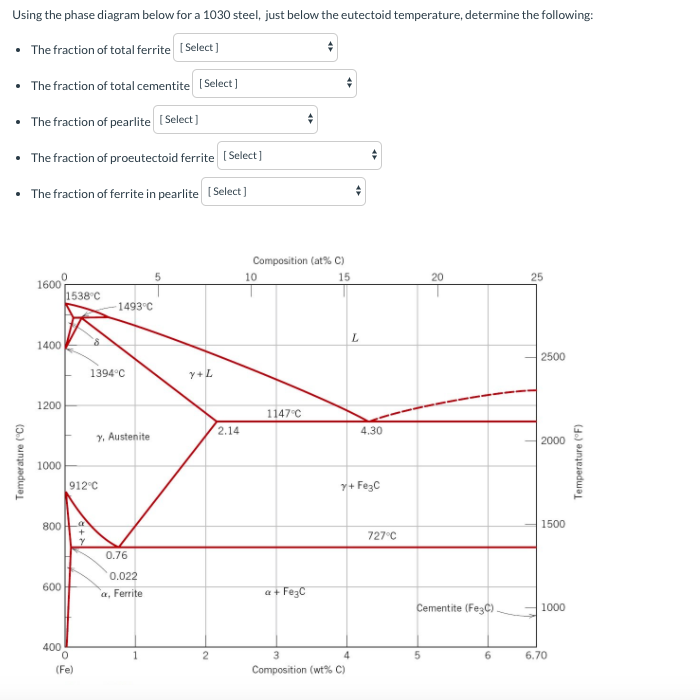

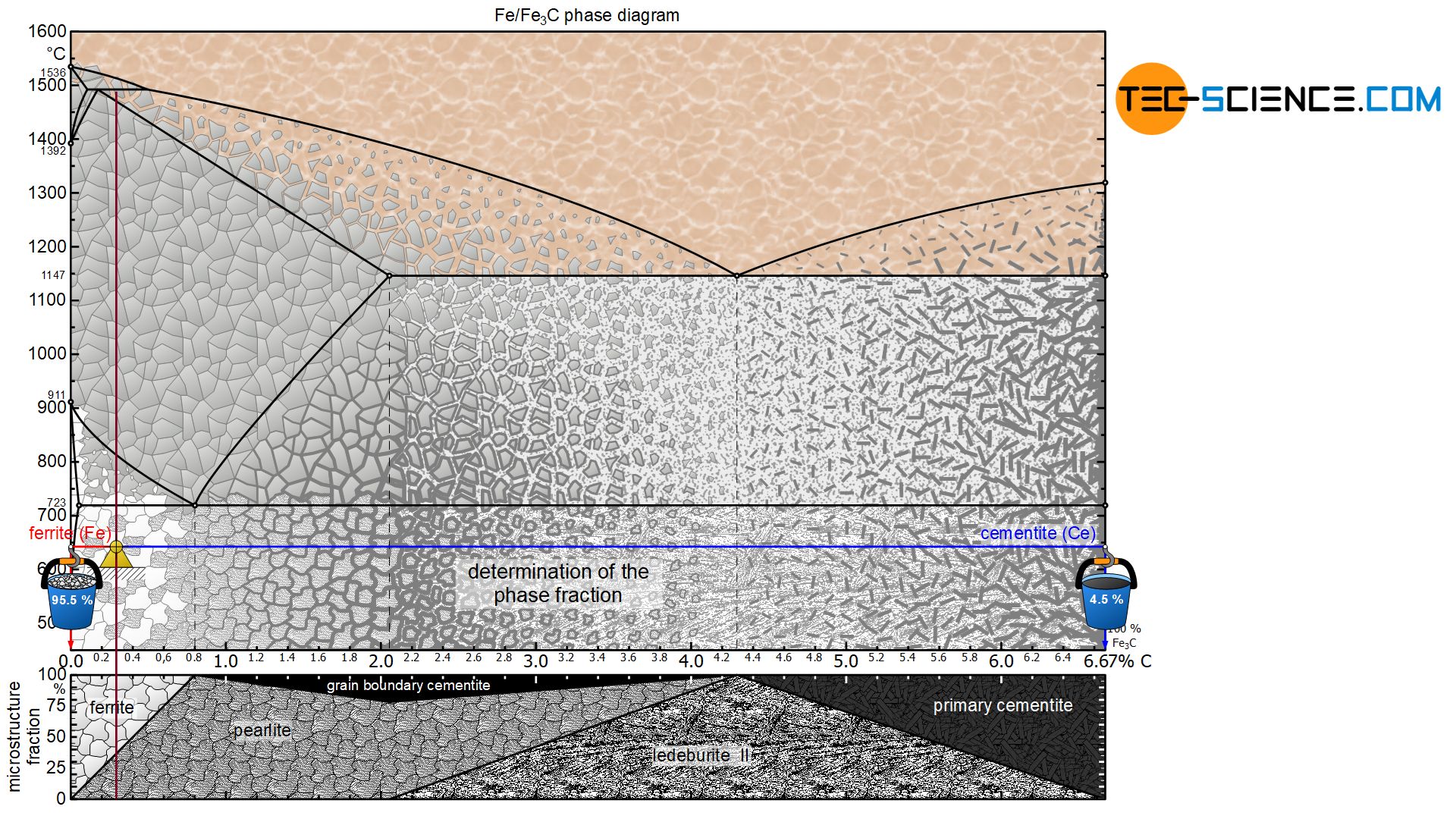

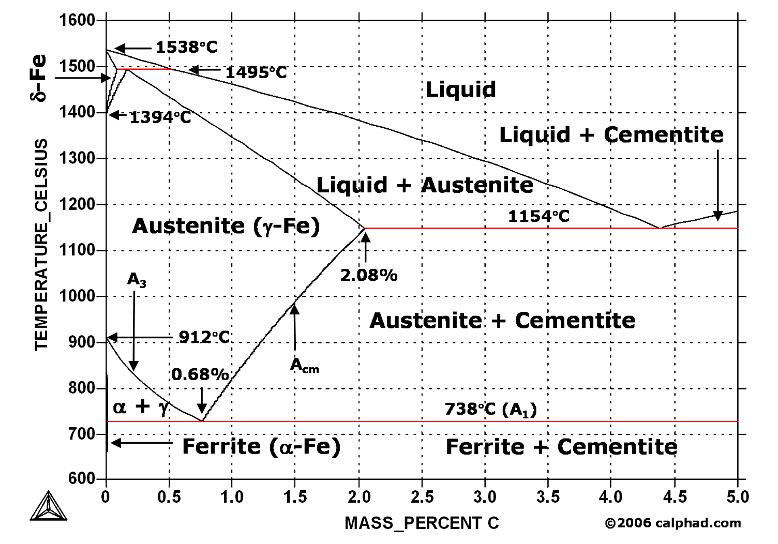

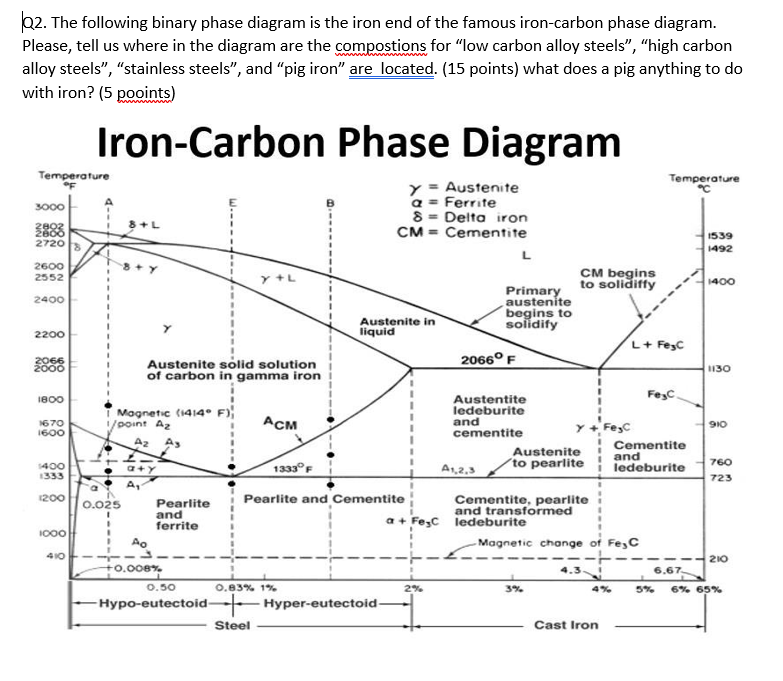

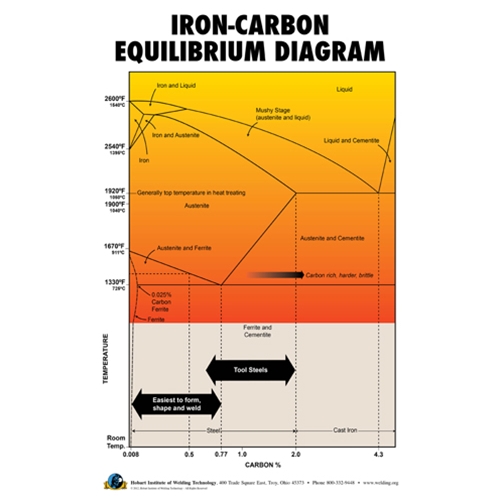

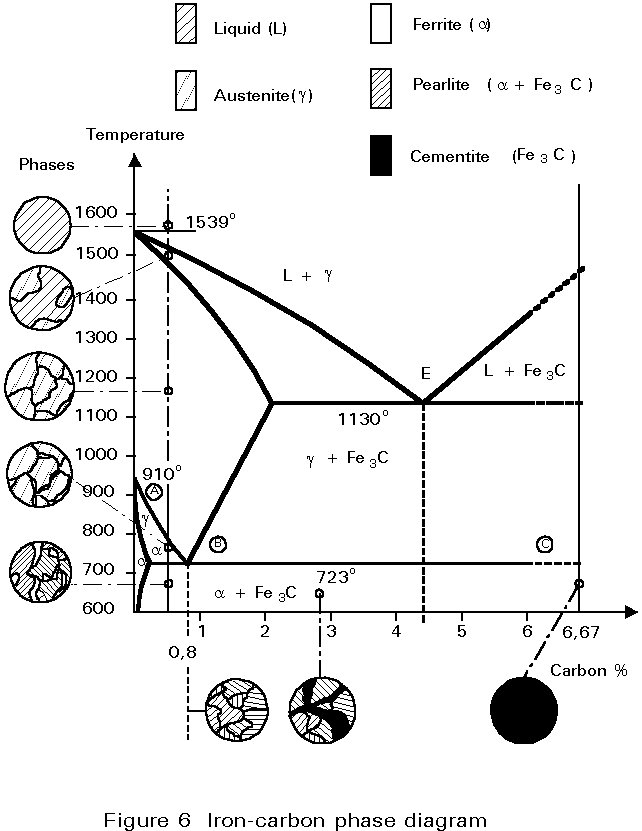

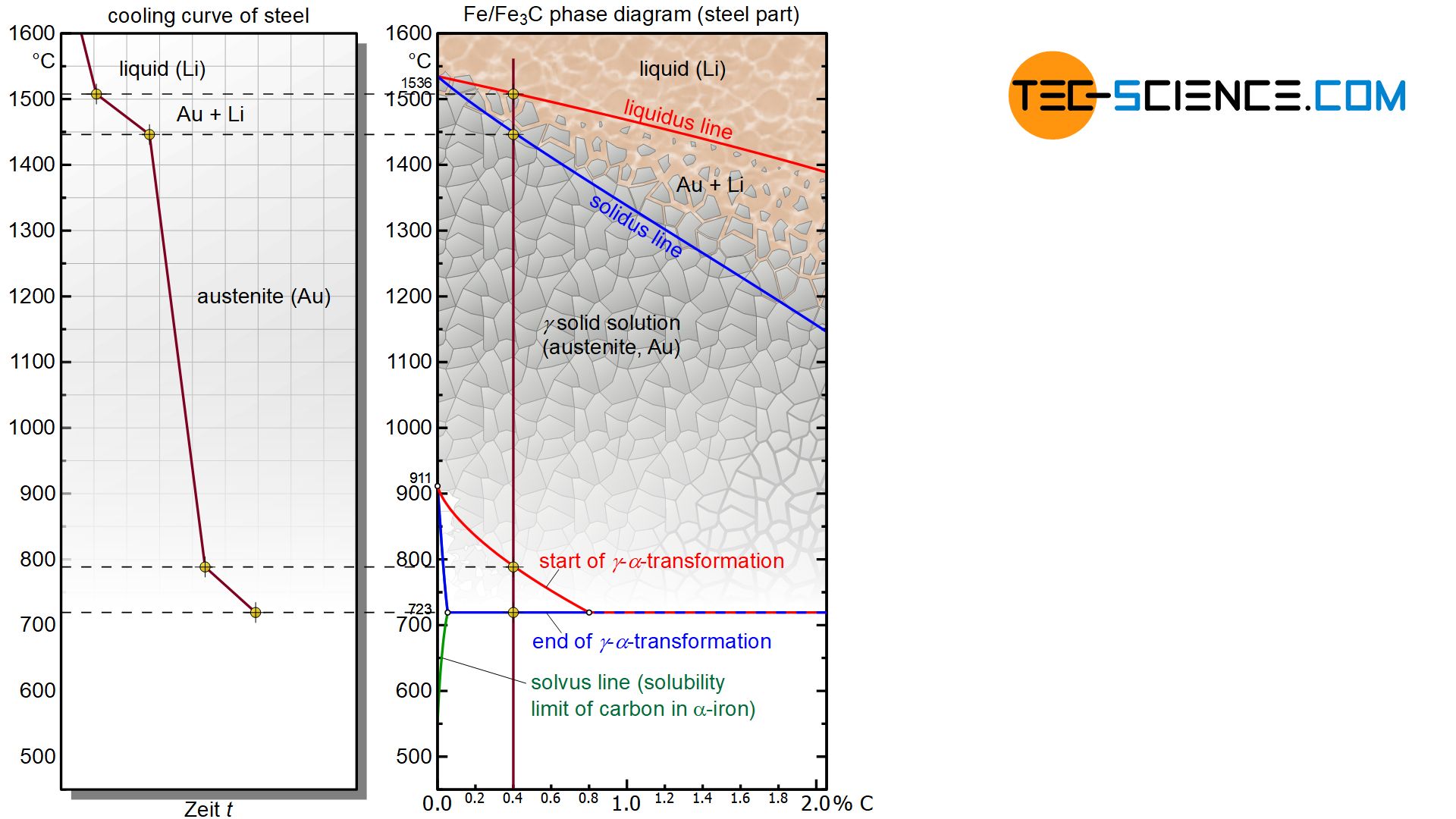

Common Phases in Steels | nuclear-power.com Common Phases in Steels Phase Diagram of Iron-carbon System In the figure, there is the iron-iron carbide (Fe-Fe3C) phase diagram. The percentage of carbon present and the temperature define the phase of the iron carbon alloy and therefore its physical characteristics and mechanical properties. Phase Diagram for Iron Carbon Alloys | Steel | Metallurgy ... A phase diagram is a chart which shows the number and nature of phases that are present in a given alloy at any temperature and composition under equilibrium condition. Fig. 1.13 shows the different constituents of steel. There are four main phases of steels, viz., ferrite, cementite austenite and pearlite.

Alloy steel - Wikipedia Alloy steel is steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties.Alloy steels are broken down into two groups: low alloy steels and high alloy steels. The difference between the two is disputed. Smith and Hashemi define the difference at 4.0%, while Degarmo, et al., define it at 8.0%.

Phase diagram of steel

Phase Diagram & Heat Treatment Of Metals - SlideShare FE-C Phase Diagram In the phase diagram Carbon percentage is shown up to 6% only since commercially pure iron contains up to 0.008% C, Steels up to 2.11% C and C.I.s up to 6.67% C. Pure iron melts at 1583o C. When it cools first it forms delta ferrite, then austenite and finally alpha ferrite. What is the Iron-Carbon Phase Diagram? - Engineering Choice Iron-Carbon Phase Diagram. The iron-carbon phase diagram is widely used to understand the different phases of steel and cast iron. Both steel and cast iron are a mix of iron and carbon. Also, both alloys contain a small number of trace elements. The graph is quite complex but since we are limiting our exploration to Fe3C, we will only be ... Steel - Wikipedia Steel is an alloy made up of iron with typically a few tenths of a percent of carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant need typically an additional 11% chromium.Because of its high tensile strength and low cost, steel is used in buildings ...

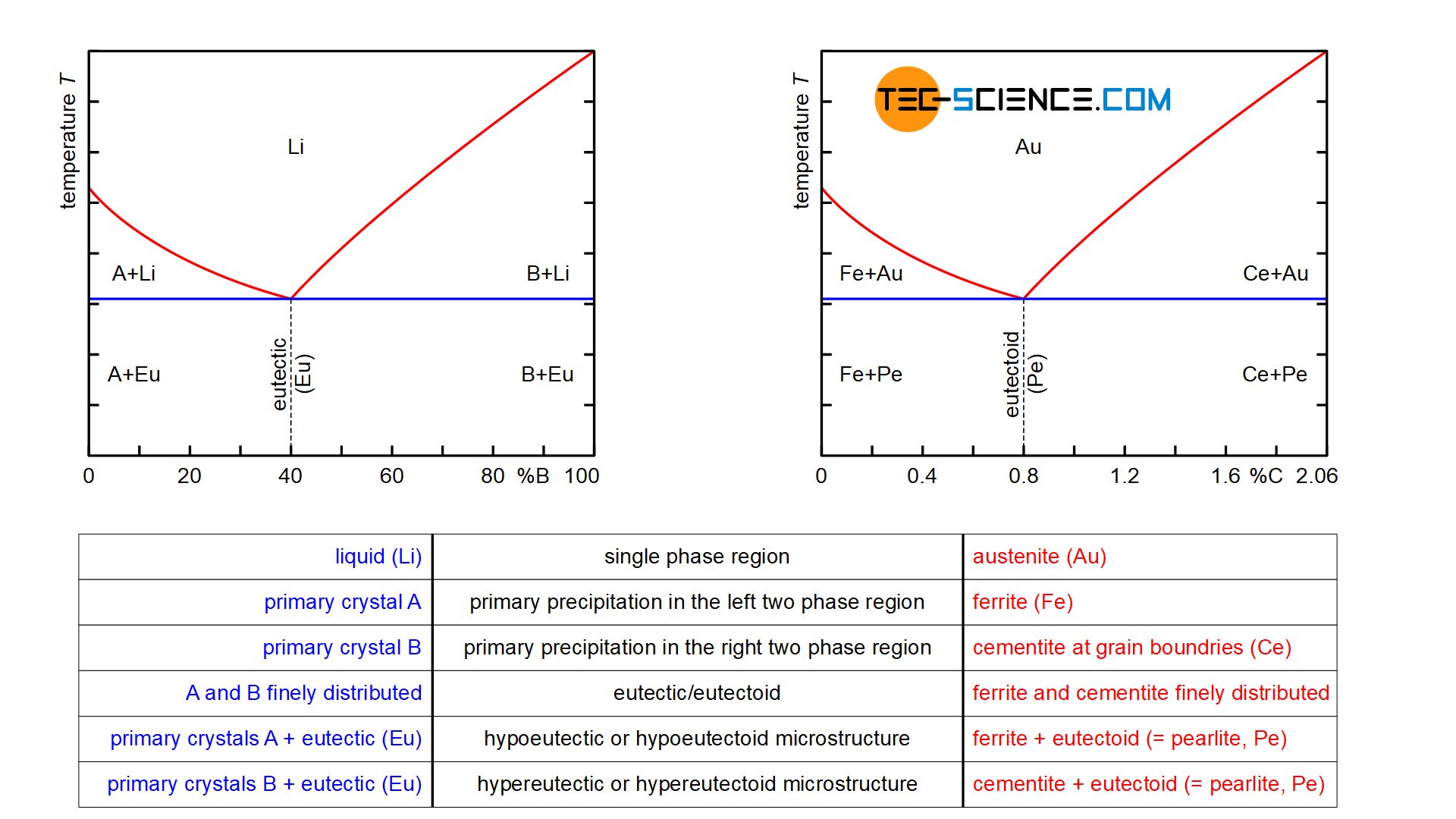

Phase diagram of steel. Phase Diagram Of Steel - phase diagram of mild steel ... Apr 21, 2022 · Phase Diagram Of Steel - 17 images - solidification of steels, ferrite martensite structure of aisi 1040 steel at 750, what is ferrite cementite austenite and pearlite quora, stress strain diagrams youtube, Phase Diagram - Industrial Metallurgists Aug 14, 2021 · An example of a commonly used phase diagram is the iron-carbon phase diagram, which is used to understand the phases present in steel. The amount of carbon present in an iron-carbon alloy, in weight percent, is plotted on the x-axis and temperature is plotted on the y-axis. Each region, or phase field, within a phase diagram indicates the phase or phases present for a particular alloy composition and temperature. Summary of the phase transformations of steel - tec-science The actual solidification process in steels takes place independently of the carbon content as in a solid solution alloy. This is shown in the phase diagram as a typical lenticular region between the liquidus and the solidus line. The carbon is completely soluble in the face-centered cubic γ-iron lattice structure immediately after solidification. 4140 Steel Phase Diagram - schematron.org 4140 Steel Phase Diagram. Transcript of ISOTHERMAL TRANSFORMATION OF STEEL. Austenite Ferrite Pearlite Bainite Martensite Tensile Test ISOTHERMAL. Bruce L. Bramfitt, Homer Research Laboratories, Bethlehem Steel Corporation. Basis of Material .. tion of the constituent on a phase diagram. Fer- rous alloy .

Fundamentals of Carbon Steel Part 1 - Phases ... It is important to note that phases in steel should not be confused with structures. Whilst there are many structures or mixtures of structures, there are only three phases involved in any steel; ferrite, cementite and austenite. The area denoted as austenite in Figure 3 is an area within which iron can retain much dissolved carbon. Calculated equilibrium phase diagram of 440C martensitic ... The equilibrium phase diagram of this stainless steel was calculated by using Thermo_Calc and JMat_Pro software. Both of these calculation methods show that the critical points of the 440C steel ... Comparison of phase transformations in steels - tec-science Note that the phase diagram of the steel was broken off at 2.06 % carbon. Normally the phase diagram on the right ends with 100 % cementite (more on this in the article here ). For hypoeutectic alloys, the residual melt is enriched with B atoms by the precipitation of the primary crystals A until the eutectic composition is finally reached. Phase Diagram of Steel - Metallurgy for Dummies Phase Diagram of Steel. Fe-Fe 3 C Phase Diagram, Materials Science and Metallurgy , 4th ed., Pollack, Prentice-Hall, 1988. Figure above shows the equilibrium diagram for combinations of carbon in a solid solution of iron. The diagram shows iron and carbons combined to form Fe-Fe3C at the 6.67%C end of the diagram.

Phase diagram of commercial 316L stainless steel plotted ... Phase diagram of commercial 316L stainless steel plotted by using ThermoCalc program. Source publication Intergranular Corrosion of 316L Stainless Steel by Aging and UNSM (Ultrasonic Nano-crystal... Carbon Steels and the Iron-Carbon Phase Diagram - IspatGuru Fig 2 Iron- carbon phase diagram Steels that are 100 % austenite must have temperature-composition coordinates within the area of austenite shown in the phase diagram at Fig 2. Steels that are ferrite must have temperature-composition coordinates in the narrow region at the lower left of the Fe-C phase diagram. Phase diagram - Wikipedia A phase diagram in physical chemistry, engineering, mineralogy, and materials science is a type of chart used to show conditions (pressure, temperature, volume, etc.) at which thermodynamically distinct phases (such as solid, liquid or gaseous states) occur and coexist at equilibrium . Contents 1 Overview 2 Types 2.1 2-dimensional diagrams TTT Diagram of steel in Material science - Materials Today For history, it should be noted that Pearlitic and Bainitic bay in the TTT diagram of steel are identified and explained by Davenport and Bay. Martensitic start and end transformation lines were later added by Cohen. Follow isothermal transformation in steel on Wikipedia for complete history. Important points to note for TTT diagram of steel are;

Three Phase Transformer Connections and Basics Where: V L is the line-to-line voltage, and V P is the phase-to-neutral voltage. A transformer can not act as a phase changing device and change single-phase into three-phase or three-phase into single phase. To make the transformer connections compatible with three-phase supplies we need to connect them together in a particular way to form a Three Phase Transformer …

Annealing of Steels - IspatGuru Fig 4 Iron-carbon binary phase diagram showing region of temperatures for full annealing. Austenitizing time and dead-soft steel - Hyper-eutectoid steels can be made extremely soft by holding for long periods of time at the austenitizing temperature. Although the time at the austenitizing temperature can have only a small effect on actual hardnesses (such as a change from 241 HB to 229 HB ...

Phase Diagram Of Steel | Metallurgy for Dummies Phase Diagram of Steel. Figure above shows the equilibrium diagram for combinations of carbon in a solid solution of iron. The diagram shows iron and carbons combined to form Fe-Fe3C at the 6.67%C end of the diagram. The left side of the diagram is pure iron combined with carbon, resulting in steel alloys. Three significant regions can be made ...

Stainless Steels - Phase Transformations and Complex ... It is evident from Figure 6 (Fe-Cr-C phase diagram) that typical martensitic steels should exhibit ferrite and M 23C 6in equilibrium at for example, 600°C. In practice, this carbide is only found after relatively long ageing. because it is preceded by Intermediate phases in the sequence cementite, M 2X and M 7C 3, leading finally to M 23C 6.

Iron-Carbon Phase Diagram Explained [with Graphs] Mar 10, 2020 · Alloy steel elements such as nickel, manganese, chromium, and molybdenum affect the position of these boundaries on the phase diagram. The boundaries may shift in either direction depending on the element used. For example, in the iron carbon phase diagram, addition of nickel lowers the A3 boundary while the addition of chromium raises it.

PDF Chapter 9: Phase Diagrams - Florida International University Phase Diagrams • Indicate phases as function of T, Co, and P. • For this course:-binary systems: just 2 components.-independent variables: T and Co (P = 1 atm is almost always used). • Phase Diagram for Cu-Ni system Adapted from Fig. 9.3(a), Callister 7e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys , P. Nash

Phase diagrams and microstructure - Stainless steels ... In order to understand stainless steel, we need to know about the phase diagrams a little. And the base phase diagram in stainless steel is the iron-chromium binary phase diagram. In the phase diagram, you can understand that at specific temperature and chemical composition, we can predict the phases the alloy can contain.

PDF Iron Carbon Phase Diagram diagram In order to understand the transformation processes, consider a steel of the eutectoid composition. 0.8% carbon, being slow cooled along line x-x'. At the upper temperatures, only austenite is present, with the 0.8% carbon being dissolved in solid solution within the FCC. When the steel cools through 723°C,

Austenitic Stainless Steels - ASM International anywhere in the portion of the Delong diagram labeled austenite shown in Fig. 1 (Ref 1). This diagram was designed to show which phases are present in alloys in the as-solidified condition, such as found in welds. Thus it also applies to castings and continuously cast products. As a practical matter of castability, the composition

Metallography of Steels - University of Cambridge The phase diagram illustrates the domains in which particular phases or combinations of phases are stable, and contains information about their equilibrium compositions. Equilibrium phase fractions can also be estimated from a knowledge of the carbon concentration of the steel and an application of the lever rule.

Chapter Outline: Phase Diagrams We will limit our discussion of phase diagrams of multi-component systems to binary alloys and will assume pressure to be constant at one atmosphere. Phase diagrams for materials with more than two components are complex and difficult to represent. An example of a phase diagram for a ternary alloy is shown for a fixed T and P below.

PDF LAB IV Heat Treatment of Steel Consider the Iron-Carbon Phase Diagram shown in your textbook. For alloys containing 0.5%C, 0.8%C and 1% C, which have been slowly cooled from the austenite region (1100oC) to room temperature, calculate the relative amounts and compositions of the phases present at room temperature. Draw the microstructure which would result in each case. 3.

Steel - Wikipedia Steel is an alloy made up of iron with typically a few tenths of a percent of carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant need typically an additional 11% chromium.Because of its high tensile strength and low cost, steel is used in buildings ...

What is the Iron-Carbon Phase Diagram? - Engineering Choice Iron-Carbon Phase Diagram. The iron-carbon phase diagram is widely used to understand the different phases of steel and cast iron. Both steel and cast iron are a mix of iron and carbon. Also, both alloys contain a small number of trace elements. The graph is quite complex but since we are limiting our exploration to Fe3C, we will only be ...

Phase Diagram & Heat Treatment Of Metals - SlideShare FE-C Phase Diagram In the phase diagram Carbon percentage is shown up to 6% only since commercially pure iron contains up to 0.008% C, Steels up to 2.11% C and C.I.s up to 6.67% C. Pure iron melts at 1583o C. When it cools first it forms delta ferrite, then austenite and finally alpha ferrite.

![Iron-Carbon Phase Diagram Explained [with Graphs]](https://fractory.com/wp-content/uploads/2020/03/Iron-carbon-phase-diagram-explained.jpg)

![Iron-Carbon Phase Diagram Explained [with Graphs]](https://fractory.com/wp-content/uploads/2020/03/Phase-diagram-of-steel-and-cast-iron.jpg)

![Portion of Fe-C equilibrium phase diagram.[5] | Download ...](https://www.researchgate.net/profile/Tianyu-Yu-4/publication/320531737/figure/fig5/AS:668390926585883@1536368223982/Portion-of-Fe-C-equilibrium-phase-diagram5.jpg)

0 Response to "40 phase diagram of steel"

Post a Comment