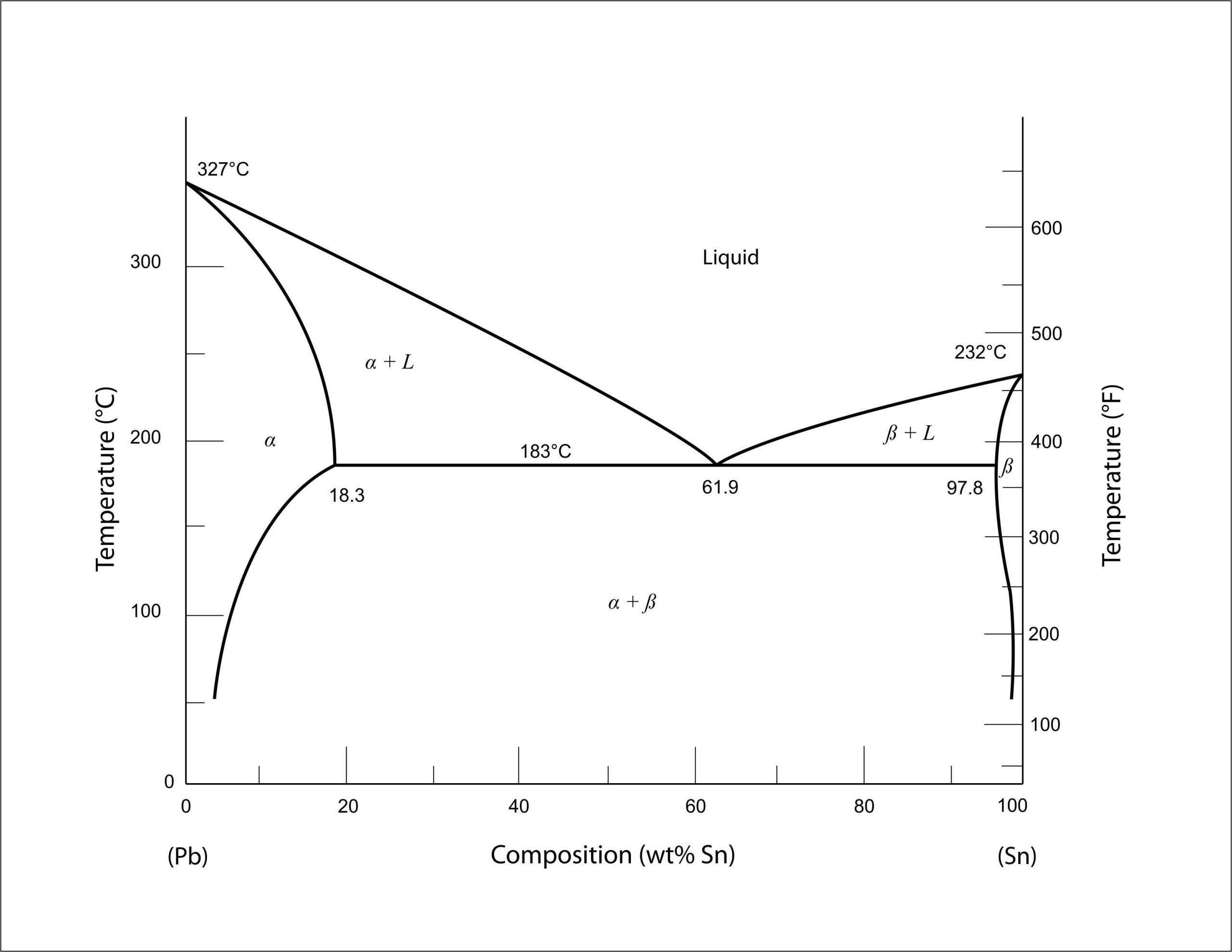

39 lead tin phase diagram

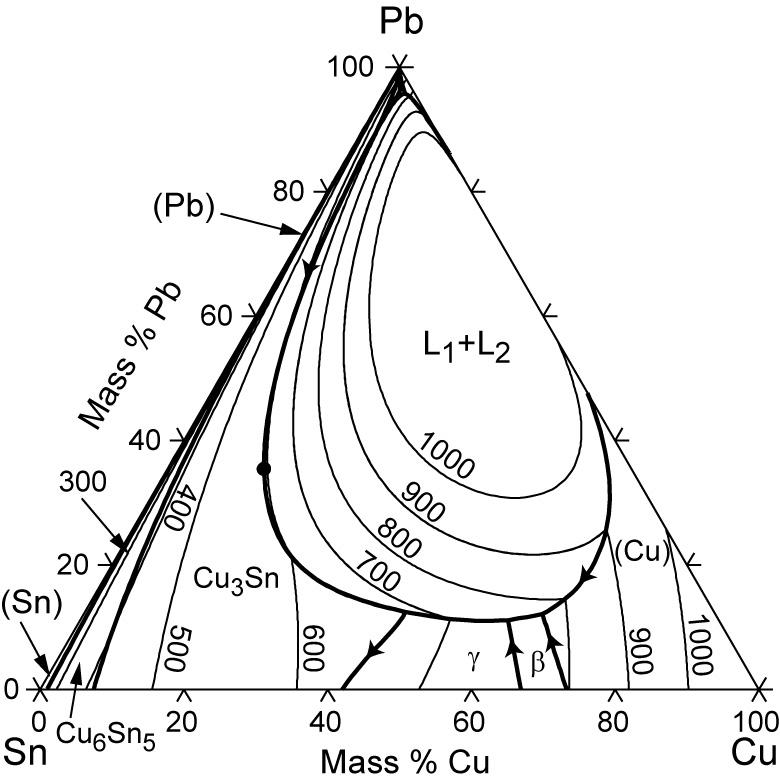

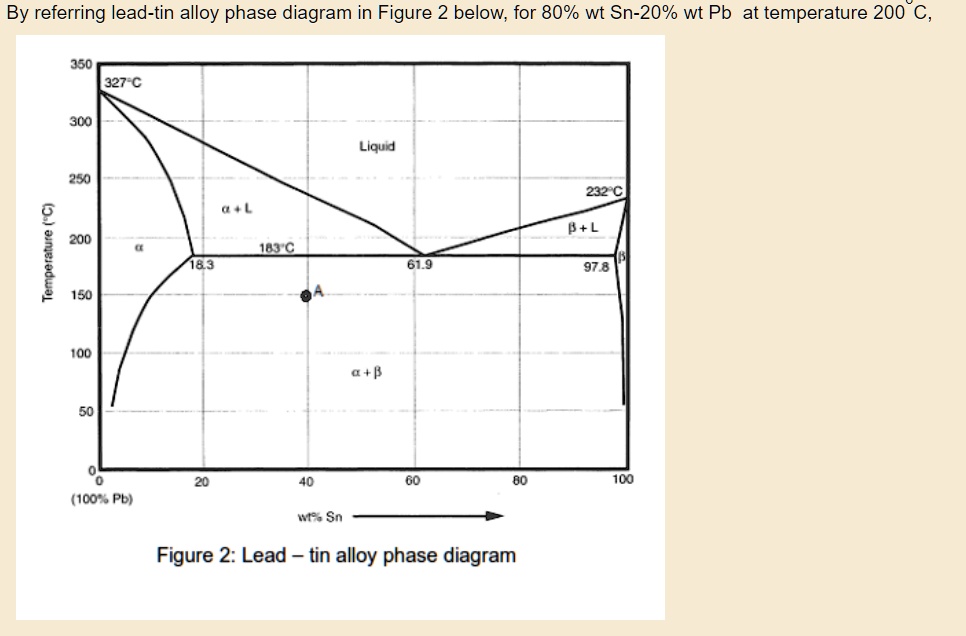

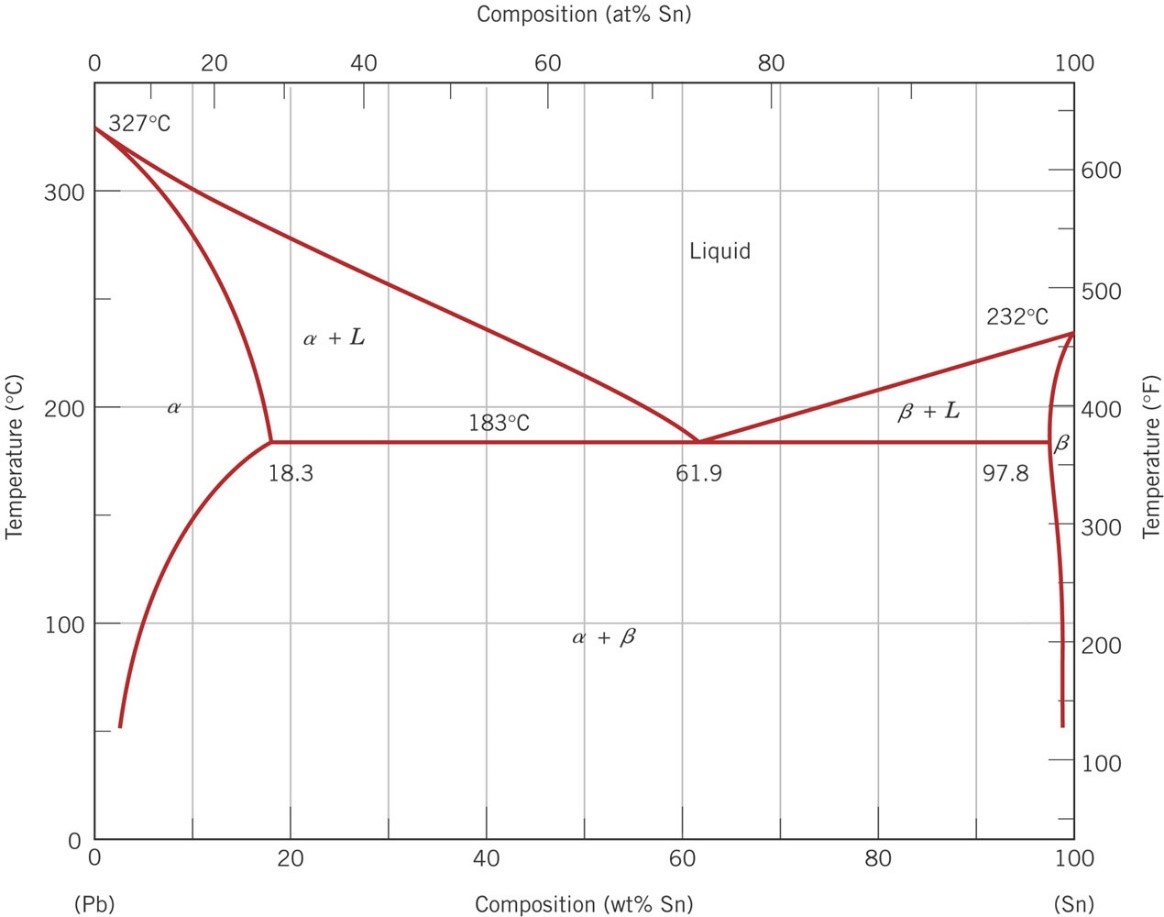

Lab 10 - Phase diagram - LEAD-TIN PHASE DIAGRAM Experiment ... 2. Record the proportion of lead-tin mixture for each sample in the table 1. 3. Set up the experiment as shown in Figure 1. 8 Figure 1: Experiment set up 4. Connect the Pasco Xplore GLX to the thermocouple. 5. Heat the crucible with Lead-Tin solid inside by using the Bunsen burner. 6. Heat the sample until they are melted. 7. Eutectic phase diagrams The tin lead phase diagram is shown in Fig. 2.12 a). The eutectic point (marked by E) has a temperature below 200 o C and a Sn concentration somewhat above ...

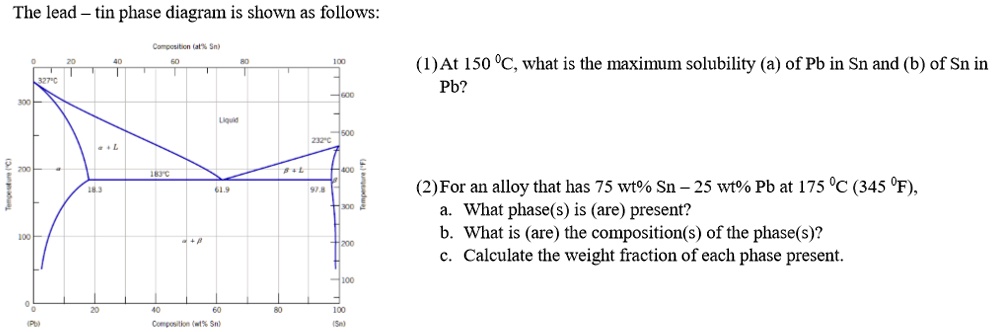

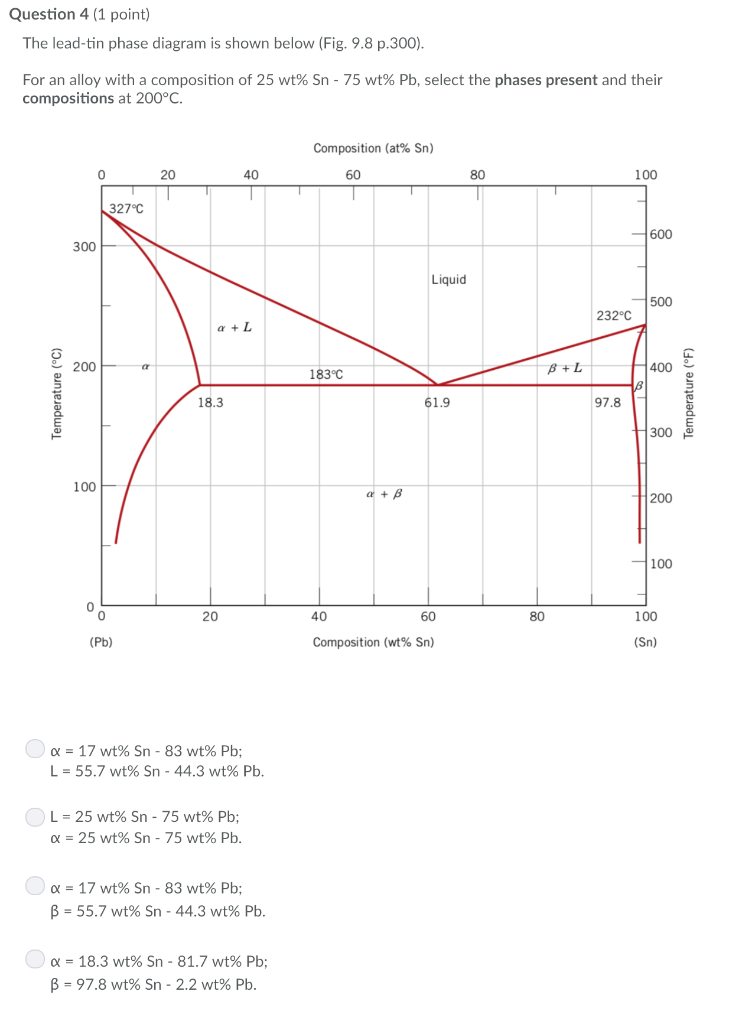

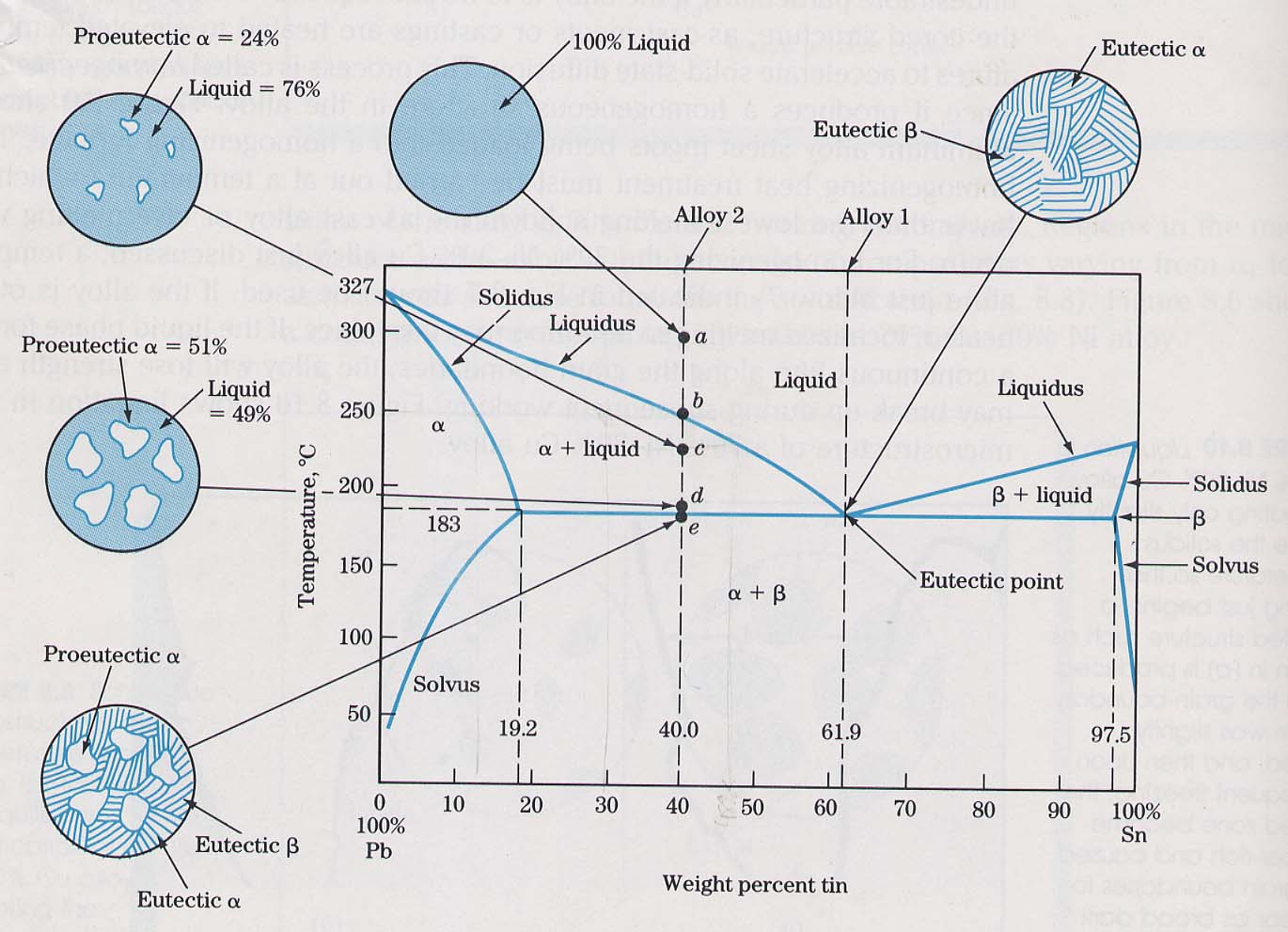

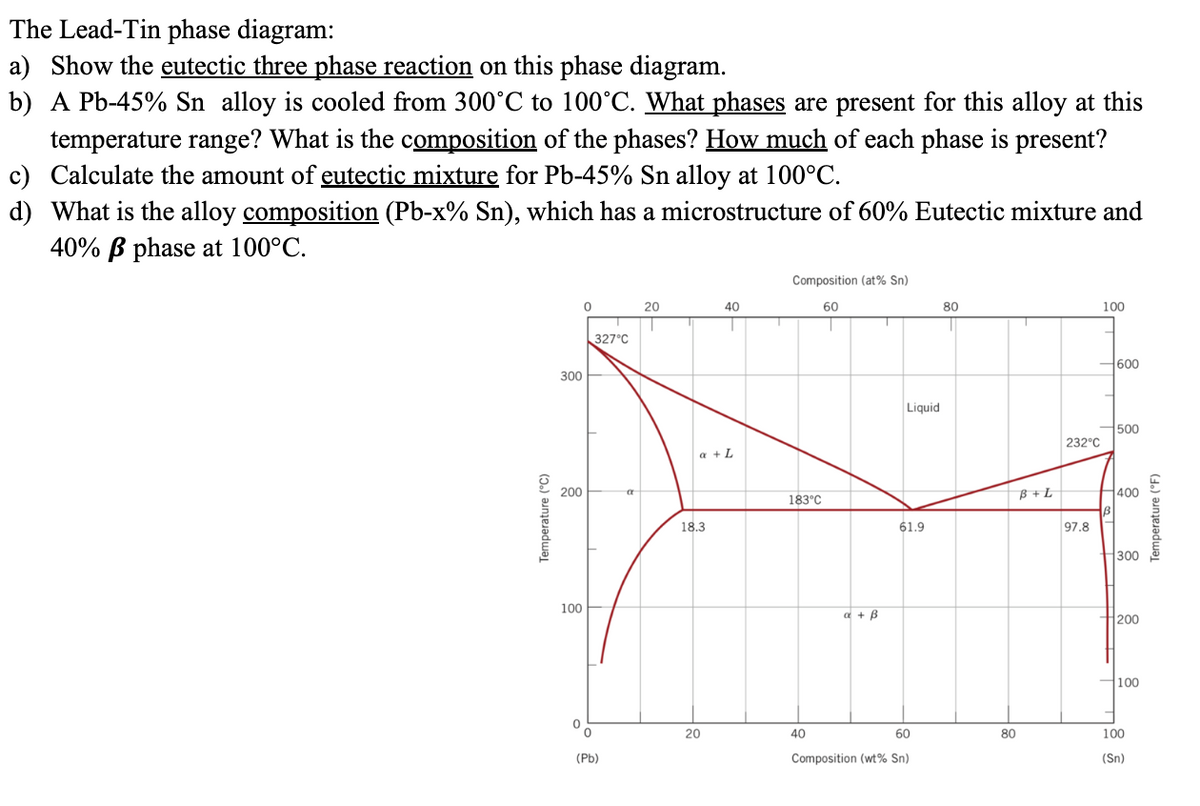

PDF Microstructure of a lead-tin alloy Interpretation of Phase Diagrams •Determining Phase Amounts: -One phase present: •Alloy is composed entirely of that phase; phase fraction is 1.0 or percentage is 100% -Two phases present: •Use the lever rule; tie line is constructed across the two-phase region at a specified temperature of the alloy

Lead tin phase diagram

Solid-liquid Phase Diagrams: Tin and Lead | ChemKey Important: This is a simplified version of the real tin-lead phase diagram. In particular, it ignores the formation of solid solutions of tin and lead. You will find the correct diagram on this NIST web page. Beware that on that page, the tin-lead axis is reversed from the one I have drawn above - in other words 100% lead is on the right ... PDF Phase Diagrams for Lead-Free Solder Alloys has been pre-tinned with a tin-lead or tin-bismuth alloy with a solder of a different composition may result in the formation of a low-melting higher-component eutectic. In this case, the multi-component phase diagram can be used to evaluate the possible effects resulting from such a contamination. Traditionally, phase diagrams are The lead-tin (Pb-Sn) phase diagram with three different ... The lead-tin (Pb-Sn) phase diagram with three different solder compositions marked out; one eutectic, and two non-eutectic (Plumber's solder and a high melting point solder). The phase diagram was...

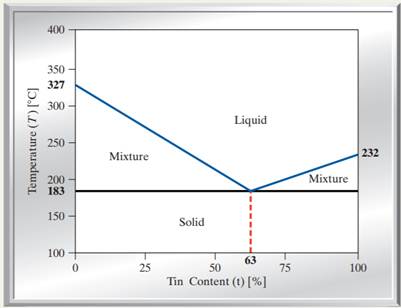

Lead tin phase diagram. solid-liquid phase diagrams: tin and lead - Chemguide Constructing the phase diagram You start from data obtained from the cooling curves. You draw a graph of the temperature at which freezing first starts against the proportion of tin and lead in the mixture. The only unusual thing is that you draw the temperature scale at each end of the diagram instead of only at the left-hand side. Solved Using the lead-tin phase diagram in Figure 6.3 ... Using the lead-tin phase diagram in Figure 6.3, determine the liquid and solid phase compositions for a nominal composition of 30% Sn and 70% Pb at 250 degree C (482 degree F). Use the inverse lever rule to determine the proportions of liquid and solid phases present in the alloy. Lab 4_ Lead-Tin Phase Diagram - Google Docs.pdf - 2 ABSTRACT ... Phase diagrams can be used to indicate alloys graph of a is then represent alloy vs. the eutectic properties. Using the four crucibles different compositions of the lead-tin alloy, the temperature of the beginning solidification was indicated for each of the graphs. Furthermore, an unknown alloy was obtained in this lab where it was about ()% Sn. From the lead-tin phase diagram, which of the following ... Question. From the lead-tin phase diagram, which of the following phases/phase combinations is present for an alloy of composition 46 wt% Sn-54 wt% Pb that is at equilibrium at. 4 4 ∘ C. 44^ {\circ} \mathrm {C} 44∘C. ? (A) α (C) β + liquid (B) α + β (D) α + β + liquid.

Solved The Lead-Tin phase diagram is presented. Answer the ... The Lead-Tin phase diagram is presented. Answer the following questions for a 90% Sn - 10 % Pb alloy. a) Estimate the temperature at which the alloy begins to solidify in degrees Celsius. Do not include units. b) Estimate the liquidus temperature in degrees Celsius. Do not include units. c) What phase (s) are present at a temperature of 100 °C? Answered: The Lead-Tin phase diagram: a) Show the… | bartleby The Lead-Tin phase diagram: a) Show the eutectic three phase reaction on this phase diagram. b) A Pb-45% Sn alloy is cooled from 300°C to 100°C. What phases are present for this alloy at this temperature range? What is the composition of the phases? How much of each phase is present? Lead Tin Phase Diagram Experiment [en5kd99g3pno] Determination of the Phase Diagram for a Lead-Tin System. Page 1 of 4 critical temperatures. Putting together all of the critical temperatures from each composition of metal mixture, will result to the construction of phase diagram. 2. Methodology Ten-gram lead-tin samples of different amounts were weighed. The Lead-Tin Phase Diagram - Making Things Fast and Slow / A ... We’ll examine the lead-tin phase diagram and look at its practical applications as an example of making something slowly. Then we’ll evaluate the TTT diagram for eutectoid steel, and compare diffusional to diffusionless transformations with the TTT diagram, monitoring how we make things rapidly. Lesson ten is a brief history of semiconductors.

The Pb−Sn (Lead-Tin) system | SpringerLink Alloy Phase Diagram Evaluations Published: 01 April 1988 The Pb−Sn (Lead-Tin) system I. Karakaya & W. T. Thompson Journal of Phase Equilibria 9 , 144-152 ( 1988) Cite this article 1318 Accesses 58 Citations Metrics Download to read the full article text Cited References Phase Diagrams - DT Online The Phase Diagram for the Eutectic Alloy of 62% Tin & 38% Lead shows that at 183 0 C it changes from : Liquid to Solid without going through any 'pasty' stage which makes it ideal for Tinman's Solder. Phase Diagram for Carbon Steel PDF Phase diagrams - weizmann.ac.il Phase diagrams 0.44 wt% of carbon in Fe microstructure of a lead-tin alloy of eutectic composition. A phase may be defined as a homogeneous portion of a system that has uniform physical and chemical characteristics What is a phase? Phase Equilibria determination of phase diagram of lead-tin system | Studymode determination of phase diagram of lead-tin system. This paper discusses the use of the cooling curves in the determination of the phase diagram of a Lead-Tin system. The inflection points of these cooling curves were obtained by melting a series of mixtures of lead and tin at varying compositions. These critical points were used on a ...

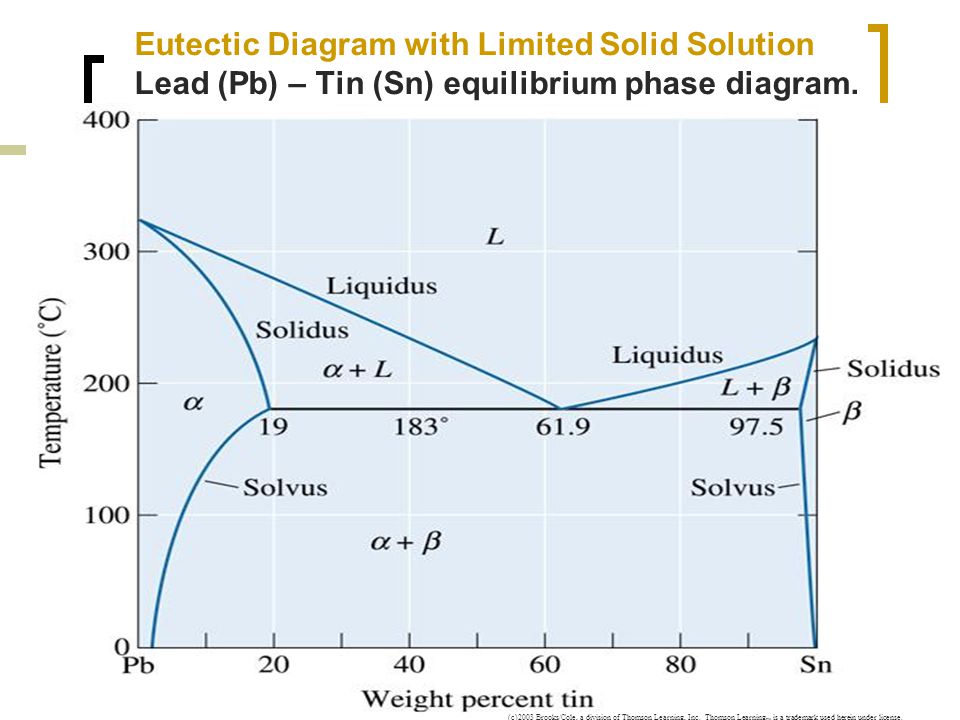

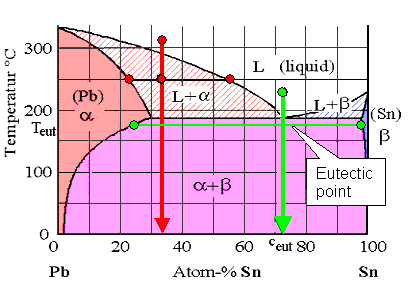

PDF Chapter Outline: Phase Diagrams Lead - Tin phase diagram Invariant or eutectic point Eutectic isotherm Temperature, ° C Composition, wt% Sn Eutectic or invariant point- Liquid and two solid phases co-exist in equilibrium at the eutectic composition CEand the eutectic temperature TE. Eutectic isotherm- the horizontal solidus line at TE.

Binary Phase Diagram: Lead (Pb) -Tin (Sn) Phase Diagram ... Binary Phase Diagram: Lead (Pb) -Tin (Sn) Phase Diagram, Identification of Phases, Estimation of Composition.Volume Fraction, Mass Fraction

Using the lead-tin phase diagram in Figure 6.3, determine ... Using the lead-tin phase diagram in Figure 6.3, determine the liquid and solid phase compositions for a nominal composition of 90% Sn and 10% Pb at 204°C (400°F).

Lead Tin Phase Diagram | Eutectic Phase Diagram | Pb-Sn ... Watch this video lecture (Lecture 10) in Material Science at Mech Online Lectures to know about Lead Tin ( Pb-Sn ) Phase Diagram. Simple explanation of Eutec...

Phase diagram of Pb-Sn (lead-tin) system - ResearchGate Download Citation | Phase diagram of Pb-Sn (lead-tin) system | This chapter provides the phase diagram of Pb-Sn (lead-tin) system. | Find, read and cite all the research you need on ResearchGate

Liquid-Solid Phase Diagrams: Tin and Lead - Chemistry ... Aug 21, 2020 · Constructing the phase diagram You start from data obtained from the cooling curves. You draw a graph of the temperature at which freezing first starts against the proportion of tin and lead in the mixture. The only unusual thing is that you draw the temperature scale at each end of the diagram instead of only at the left-hand side.

Phase diagrams lead-tin - Big Chemical Encyclopedia The lead-tin diagram has one line like this - it runs across the diagram at 183°C and connects (Sn) of 2.5 wt% lead, L of 38.1% lead and (Pb) of 81% lead. Just above 183°C an alloy of tin -i- 38.1% lead is single-phase liquid (Fig. 3.5). Just below 183°C it is two-phase, (Sn) -i- (Pb).

Lead Tin Phase Diagram Experiment | PDF | Phase Diagram ... Lead-Tin Phase Diagram [3] For binary systems, two solid phases and , are to be distinguished. These phases may have identical crystal structures but usually do not; each, of course, has the crystal structure of the component with which it is associated [2]. Three two-phase regions are designated in the figure above namely, L + , L + and + . The

Tin-Lead Alloy System's Binary Phase Diagram - MD ... There are two solid phases in the Tin-Lead alloy system that can be seen on the left and right sides of the diagram. The right side solid phase is called as alpha phase and the left side solid phase is called the beta phase in the Sn-Pb alloy system. Upon the upside lines of these solid phases, the alloy system turns into a solid+liquid phase.

EUTECTICS - A Practical Guide to Phase Diagrams Eutectics Below is the phase diagram of the lead (Pb)-tin (Sn) system. In this section, the Pb-Sn phase diagram will be discussed in detail, but first there a few basic components of phase diagrams to discuss. First there are the axes. The vertical axis shows temperature, while the horizontal axis shows the concentration of some species.

PDF CHAPTER 9 PHASE DIAGRAMS PROBLEM SOLUTIONS ε and phases ... mass fraction of each phase is 0.5, estimate: (a) The temperature of the alloy (b) The compositions of the two phases Solution (a) We are given that the mass fractions of α and liquid phases are both 0.5 for a 30 wt% Sn-70 wt% Pb alloy and asked to estimate the temperature of the alloy. Using the appropriate phase diagram, Figure 9.8, by trial

The lead-tin (Pb-Sn) phase diagram with three different ... The lead-tin (Pb-Sn) phase diagram with three different solder compositions marked out; one eutectic, and two non-eutectic (Plumber's solder and a high melting point solder). The phase diagram was...

PDF Phase Diagrams for Lead-Free Solder Alloys has been pre-tinned with a tin-lead or tin-bismuth alloy with a solder of a different composition may result in the formation of a low-melting higher-component eutectic. In this case, the multi-component phase diagram can be used to evaluate the possible effects resulting from such a contamination. Traditionally, phase diagrams are

Solid-liquid Phase Diagrams: Tin and Lead | ChemKey Important: This is a simplified version of the real tin-lead phase diagram. In particular, it ignores the formation of solid solutions of tin and lead. You will find the correct diagram on this NIST web page. Beware that on that page, the tin-lead axis is reversed from the one I have drawn above - in other words 100% lead is on the right ...

0 Response to "39 lead tin phase diagram"

Post a Comment