37 hydraulic brake system diagram

Hydraulic brake is a type of braking system which is widely used in the automobiles with the application of the hydraulic fluid. The working principle of hydraulic braking system is purely based upon Pascal's law, which states that the intensity of pressure exerted inside a closed system by the liquid is always equal in all the directions.

Symbol Of Pump Used In Hydraulic System Circuit Diagram. 3. Hydraulic Motor . A hydraulic motor is a mechanical hydraulic actuator that converts hydraulic energy or hydraulic pressure into torque and angular displacement / rotation. Types Of Hydraulic Motors And Their Symbol Used in Hydraulic Circuit Diagram. 4. Hydraulic Cylinder

Hydraulic systems are often used in press work or other applications where the work piece must be held in place. With the basic function understood, a detailed study of the diagram can be accomplished using a step-by-step analysis of each numbered local area in the diagram. LOCAL AREA NUMBER 1 Symbol for an open reservoir with a strainer.

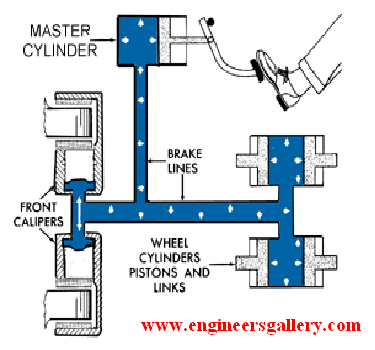

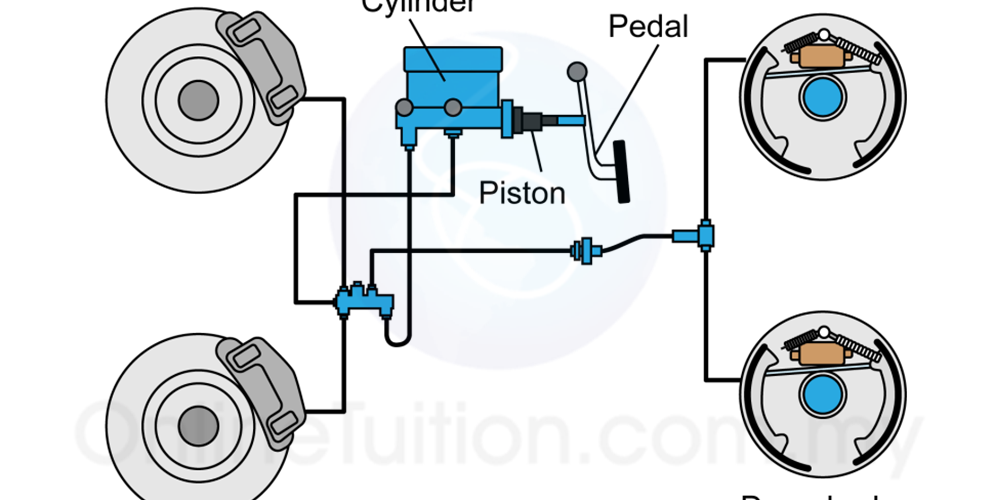

Hydraulic brake system diagram

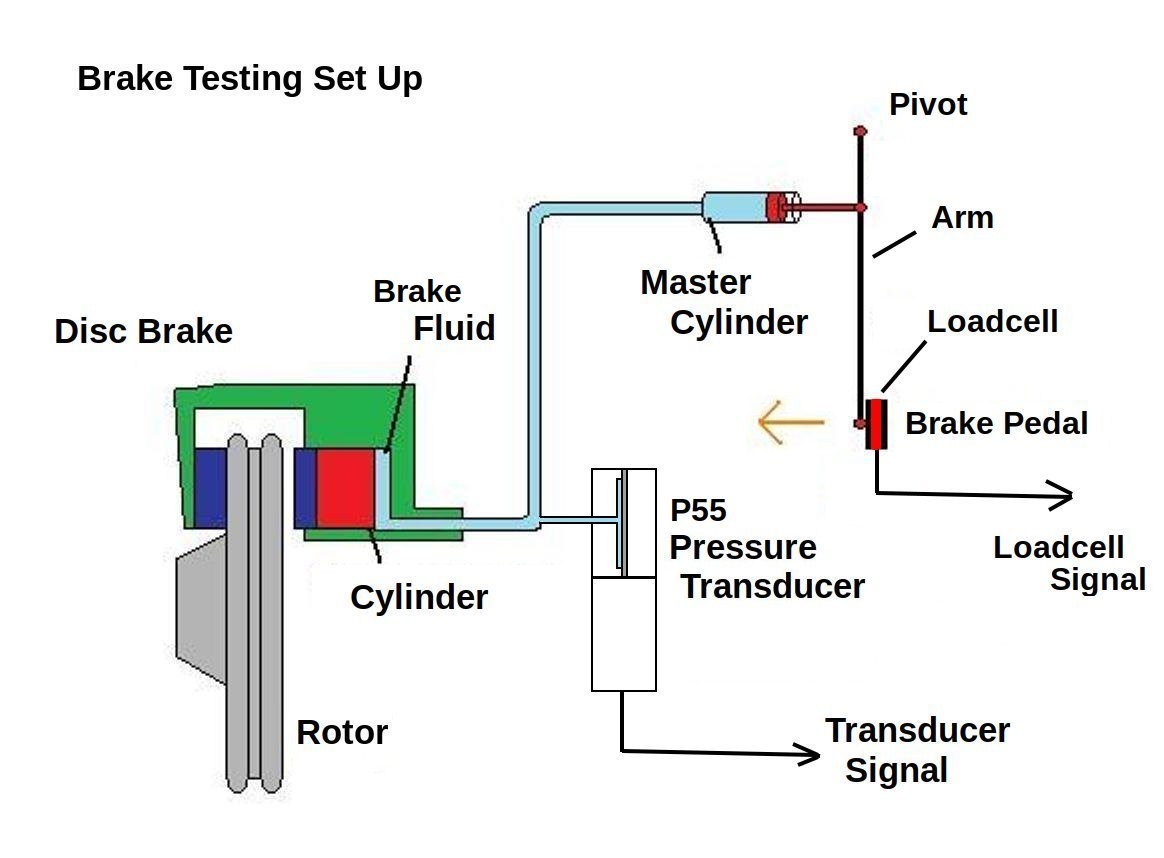

Each brake system consists of a Dellner Brakes type SKD 2x100 hydraulic pressure applied disc brake working on an 1160 mm (45.7 in) diameter disc and a pressure intensifier system. The brakes are actuated with up to 150 bar (2,180 psi) of hydraulic pressure that is generated through a pneumatic...

equipped with hydraulic brakes, built after August 21, 2006 feature the Meritor WABCO Full Power Brake system. The Full Power Brake system provides better pedal feel, shorter stopping distances, antilock brakes, and traction control. But the Full Power Brake system offers a lot more, like Electronic Brakeforce Distribution to compensate for axle

dustry. The hoist brake system consists of three subsystems which spans across three technical domains containing electrical, hydraulic and mechanical compo-nents. The different subsystems of the brake system are briefly presented in the following. 1.2.1 Brake Control System The control system mainly comprises a main control unit (MCU), a ...

Hydraulic brake system diagram.

brake rotor and caliper. The wheel hub and brake assembly components should be thoroughly wetted to suppress dust before the brake shoes or brake pads are remov Wiped. e the brake parts clean with a cloth. c. If an enclosed vacuum system or brake washing equipment is not availabl e, employers may

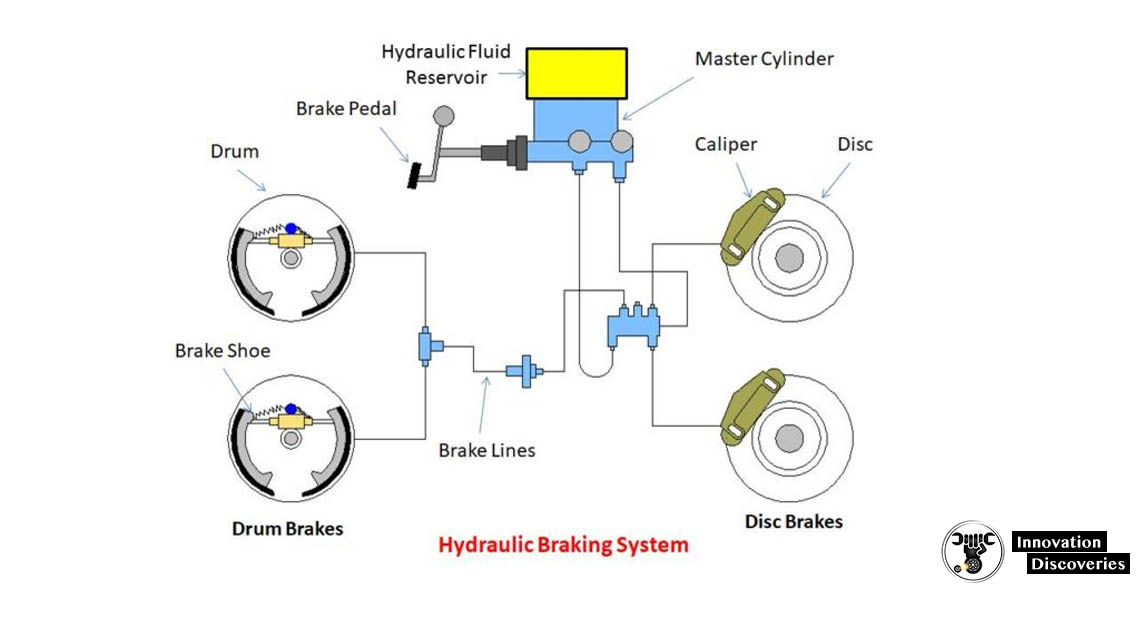

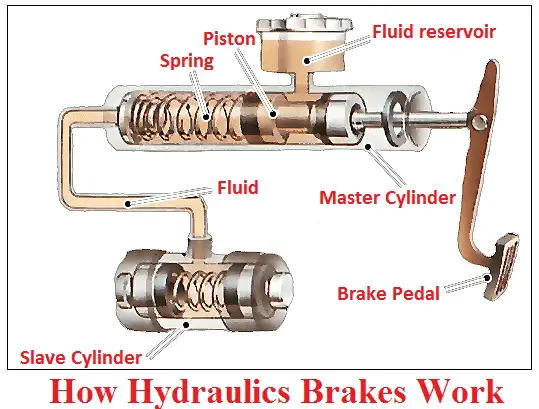

Let's see the Hydraulic Braking system working in the stepwise:- 1) When the driver presses the brake pedal, the piston presses the oil inside the master cylinder. 2) Oil flows from the master cylinder to cylinder 2 through a pipeline. 3) Now, Oil enters inside the cylinder 2. Hence both piston expands due to oil pressure.

The hydraulic brake system works with the principle of pascal's law. The laws state whenever pressure is applied on fluid it travels uniformly in all the directions. Today we'll be looking at the definition, functions, construction, applications, components, diagram, types, working, as well as advantages and disadvantages of the hydraulic ...

A hydraulic brake is an arrangement of braking mechanism which uses brake fluid, typically containing glycol ethers or diethylene glycol, to transfer pressure from the controlling mechanism to the braking mechanism. Contents 1 History 2 Construction 3 System operation 4 An example of a hydraulic brake system 5 Component specifics 5.1 Power brakes

Sep 19, 2016 · A 2 PSI residual pressure valve (RPV) is needed in the disc brake circuit, and a 10 PSI RPV is required in the drum brake circuit as well as an adjustable proportioning valve (APV). This diagram illustrates the 2 most common types of fittings used in street rod brake systems. The first is the inverted flare type, which is used by most domestic production cars and trucks, and on the bottom is the -3 AN (which is pronounced as dash three A N or number three A N).

Definition of Brake System: A brake is one of the most important controls of the vehicle. This is a combination of some interactive parts. It absorbs energy from the moving part and slows down the vehicle with the help of friction.. Every vehicle has its own braking system to stop that vehicle.

Class 5 to 7 Truck & Bus Hydraulic Brake System Diagnostic Guide 4 Preface Purpose of This Diagnostic Guide The purpose of this diagnostic guide is to assist Class 5 to 7 hydraulic brake repair technicians to more accurately and quickly diagnose the most likely causes of a customer's brake related complaint.

system draws its fluid from the standpipe, which is located at a higher elevation. This ensures an adequate fluid supply to the secondary system if the main system fails. Figure 1-2. Hydraulic Reservoir Pressurized With Hydraulic Fluid. HYDRAULIC FILTER Contamination of hydraulic fluid is one of the common causes of hydraulic system troubles.

Brake hydraulics A hydraulic brake circuit has fluid-filled master and slave cylinders connected by pipes. Master and slave cylinders The master cylinder transmits hydraulic pressure to the slave cylinder when the pedal is pressed. When you push the brake pedal it depresses a piston in the master cylinder , forcing fluid along the pipe.

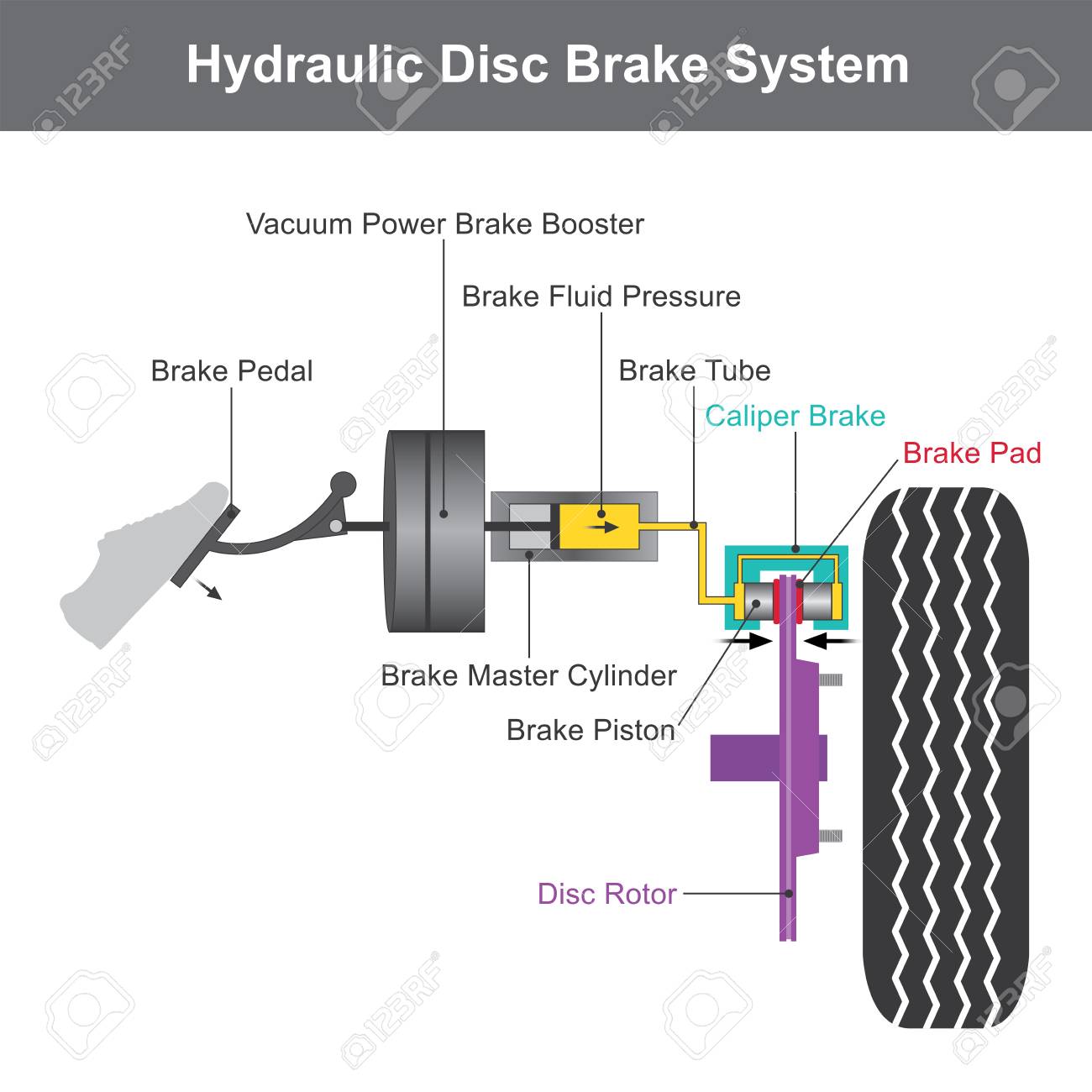

May 28, 2019 · Car Brake System Diagram In this image, you will find power booster, master cylinder, ABS, caliper assembly, ABS hydraulic unit, hydraulic fluid lines, brake pedal, rotor in it. You may also find ABS system wiring, drum, parking brake cable, electronic ABS controller, car brake system, brake system of car, car, car internal structure in this image.

4. The air brake system is used in trucks, buses, trains, etc. 4. Hydraulic oil brake system is used for light vehicles such as cars, light-duty trucks, etc. 5. Air compressor uses a certain amount of engine power. 5. No engine power is used. 6. It is not self lubricating. 6. Hydraulic brakes are self lubricating.

steps on the brake pedal. If the system is equipped with the optional power park brake, the HCU also supplies the energy to release and control the service and park brakes. The Meritor WABCO HPB system for trucks is illustrated in Figure 1.8. A complete HPB system layout, with hydraulic brake lines, appears in the Appendix. Figure 1.8 Figure 1 ...

HEAVY-DUTY BRAKE FLUID Some hydraulic brake systems use a non-petroleum-based hydraulic brake fluid such as SAE J1703 or SAE J17021. Other hydraulic systems use petroleum-based brake fluids (mineral oil). It is important to ensure that the correct brake fluid is used in the vehicle brake system and incompatible fluids are not mixed.

Power Brake Diagram. HowStuffWorks. Now let's put the parts together to see how power brakes work as a whole. This diagram provides both a closeup view and an example of where the brakes are located in your vehicle. For more articles on brakes and related automotive topics, check out the links below.. Advertisement.

Hydraulic braking system is a type of braking system in which unlike the mechanical braking system, hydraulic fluid is used to transmit the brake pedal or brake lever force from the brake pedal or brake lever to the final drum shoes or disc caliper in order to achieve braking.

hydraulic brake actuation unit. A typical assembly is shown in Figure 1. The booster reduces the pedal effort required to apply the brakes as compared to a non-power system. General Description Hydro-MaxTM Booster The hydraulic booster is comprised of an open center valve and reaction feedback mechanism, a

hydraulic braking system diagram The master cylinder is connected to all the four-wheel cylinders by tubing or piping. All cylinders and tubes are fitted with a fluid that acts as a link to transmit pedal force from the master cylinder to wheel cylinders. Brake Fluid The fluid-filled in the hydraulic brake system is known as brake fluid.

Taking one wheel's hydraulic brake circuit as an exam- ple, a schematic diagram of a hydraulic braking system is shown in Figure 1. The inlet valve (normally open) and the outlet valve (normally...

The disc brake rotor may break, and you may fall off the bicycle. • Vapor lock may occur if the brakes are applied continuously. To solve this problem, momentarily release the lever. Vapor lock occurs when the oil inside the brake system becomes heated, which causes the water or air bubbles inside the brake system to expand.

In a hydraulic brake system, braking is accomplished by actuating the lever, which advances the master piston inside the lever body and forces fluid into the brake hose. The fluid then moves into the caliper and presses against the slave pistons.

Diagrams and Schematics Index Section A - Front/Rear Axle Assemblies and Suspension ... Suspension: Wheels Section B - Brake Assemblies and Components Hydraulic Brake System Master Cylinder Brake Booster Clutch/Brake Pedals Section C - Steering Components Steering Column Steering Box Steering Linkage Section D - Frame and ...

Dont forget the brake line Here is a gm diagram I found useful. Hydro-boost power assist was introduced in by Bendix as an alternative to the vacuum booster. The hydro-boost uses the hydraulic.Oct 26, · dodge colt with miles on a liter 4G93 mitsu engine. I pulled the EGR valve temp sensor to check it and alot of liquid came pouring out of the ...

A closed system also utilises a reservoir of brake fluid, however the lack of an internal bladder to compensate for the expansion in brake fluid and also to compensate for pad wear means that any adjustments to the levels of brake fluid within the working system need to be made manually. Brake Lines. Hydraulic brake lines or hoses play the ...

![Hydraulic brake system schematics. Source: [13] | Download ...](https://www.researchgate.net/profile/Luiz-Goes-2/publication/321948638/figure/fig1/AS:613945450717190@1523387410170/Hydraulic-brake-system-schematics-Source-13.png)

0 Response to "37 hydraulic brake system diagram"

Post a Comment